.png)

.png)

Explore our specialized knowledge in mineral beneficiation across various types of ores, delivering high-quality solutions for industrial needs.

We specialize in beneficiation processes for a wide range of minerals, enhancing their quality and usability for various industrial applications.

Coal washeries are facilities that process coal to remove impurities and improve its quality. Non-coking coal is primarily used for power generation and has higher ash content, requiring washing to reduce ash and enhance calorific value. Coking coal, essential for steel production, undergoes beneficiation to lower ash and sulfur content, making it suitable for coke manufacturing in blast furnaces. Processes include jigging, dense medium separation, and flotation to separate coal from gangue materials.

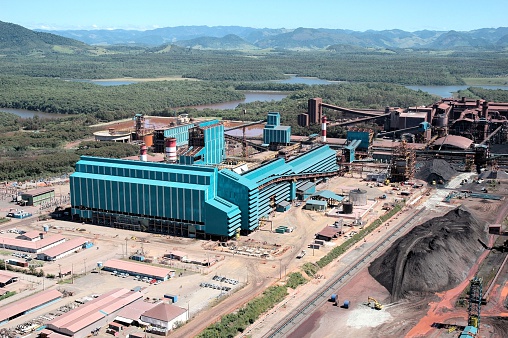

Iron ore beneficiation involves processes to improve the quality of iron ore by removing impurities and increasing iron content. Common methods include crushing, grinding, magnetic separation, flotation, and gravity separation. These techniques separate valuable iron minerals like hematite and magnetite from gangue materials such as silica and alumina. The goal is to produce high-grade concentrates suitable for steel production, enhancing efficiency and reducing energy consumption in smelting.

Sand beneficiation aims to purify sand by removing impurities like clay, silt, and organic matter. Processes include washing, scrubbing, attrition grinding, and screening to achieve desired particle size and quality. For foundry sand, differential attrition grinding separates olivine from gangue, producing rounded grains with low impurity content. This enhances sand's suitability for industrial applications such as glassmaking, construction, and metal casting.

Lead-zinc beneficiation processes separate lead and zinc minerals from gangue in complex ores. Flotation is the primary method, using collectors and depressants to selectively float sulfide minerals like galena and sphalerite. Gravity and magnetic separation may be used for oxide ores. The goal is to produce high-grade concentrates for smelting, maximizing recovery while minimizing environmental impact.

Phosphate beneficiation extracts phosphate rock from matrix, removing impurities like silica and clay. Processes include crushing, washing, flotation, and gravity separation. In Florida, draglines mine the matrix, which is slurried and screened. Flotation separates phosphate from sand, producing concentrate for fertilizer production. Tailings management is crucial for environmental sustainability.

Gold beneficiation recovers gold from ores using gravity separation, flotation, cyanidation, or combinations. For placer gold, gravity methods like jigging and shaking tables are effective. Sulfide ores require flotation or cyanide leaching. Processes aim to maximize recovery while minimizing costs and environmental impact.

Copper beneficiation processes extract copper from ores, primarily through flotation for sulfide ores and leaching for oxides. Crushing and grinding prepare the ore, followed by flotation to produce concentrate. This is smelted and refined into copper products. Efficient methods reduce costs and environmental impact.